We vinden het belangrijk te verduurzamen met projecten die aansluiting vinden bij de klant. Maar dat is niet onze belangrijkste motivatie. Dat is namelijk dat we de wereld graag een stukje mooier willen maken. Dat wil jij toch ook? Dit zijn een aantal andere projecten die we afgelopen jaar hebben uitgevoerd waar we trots op zijn:

B Corp gecertificeerd

Sinds juni 2025 is Allshoes B Corp gecertificeerd met een score van 99,2.

Better materials & design

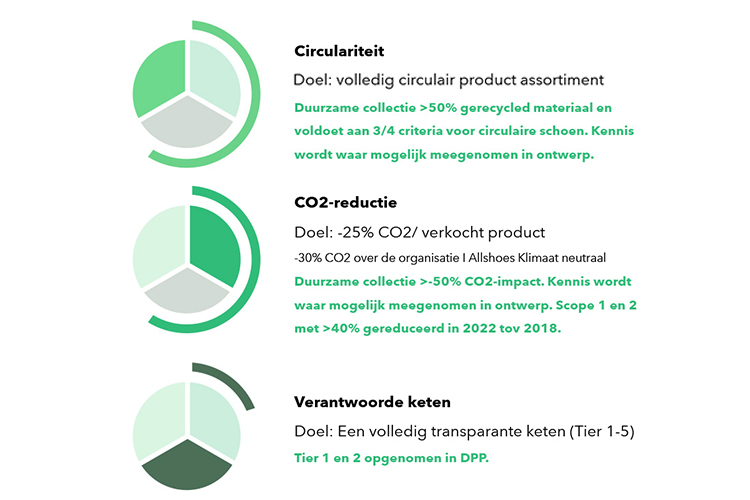

Lancering van de duurzmame Redbrick- en Grisport-collectie (>50% gerecycled)

Herontwerp van de schoenendoos (-60% inkt, van FSC-karton!)

Driving Change

Eerste Sustainability Event in 2023

Digitale Product Paspoorten voor een groot deel van onze collectie

Sustainable operations

CO2-uitstoot scope 1 en 2 gehalveerd tov basisjaar 2018

CO2-dashboard voor monitoring

Close the loop

GGA opgericht en omgezet naar een stichting

Verplichte schoeninzameling vanaf 2026

In gesprek met de staatssecretaris over de UPV voor veiligheidsschoenen

Supporting people

Drie vrijwilligersdagen per jaar per medewerker

Allshoes gecertificeerd als Great Place To Work

Donaties van veiligheidsschoenen aan diverse goede doelen